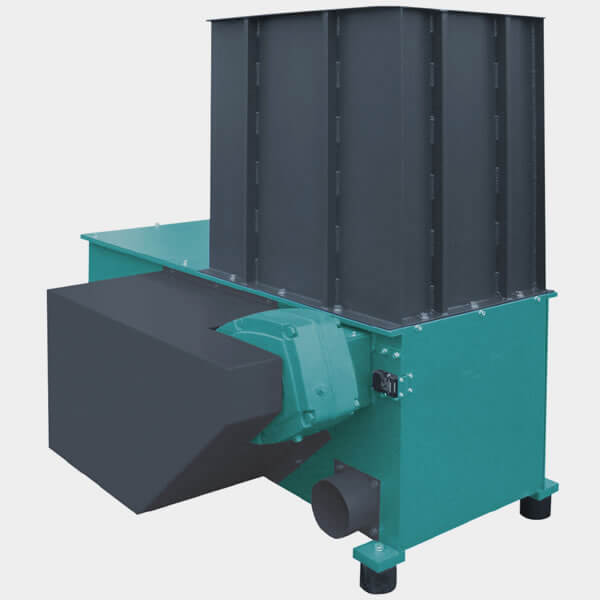

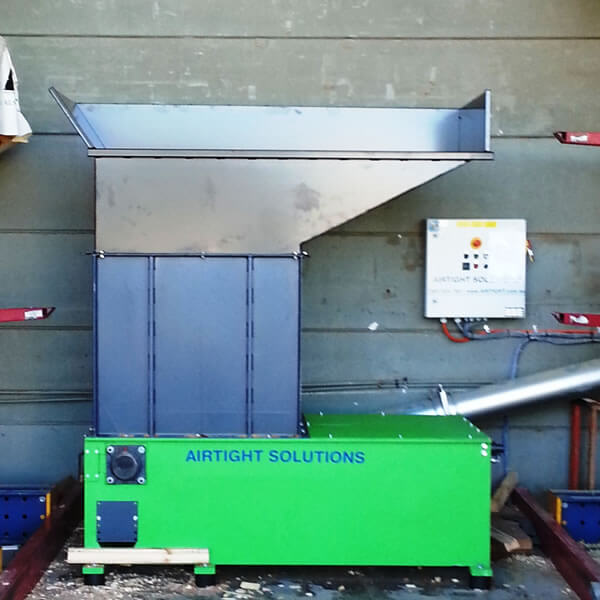

Airtight EZ Shred 6

Airtight Solutions have expanded to offer waste reduction options for wood waste, rubber, aluminium and paper, complementing the existing range of modular dust collectors, ducting and flexible hoses.

Benefits of Airtight EZ Shredders:

- Lower noise levels are ensured by the slow rotating rotor and the material pushed against it by a hydraulic pusher.

- Lower power consumption, less impact and reduced maintenance is guaranteed as the product is grinded down instead of chipped.

- There is less strain on the equipment as the control unit measures and adjusts the exact amount of force that is used during the grinding process.

- The fixing screws are protected from wear and tear as the cutter heads are instead mounted on solid blocks.

- The diamond shape of the cutter heads means they face less impact when cutting than a round cutter head. The cutter head can be rotated up to four times, which results in lower running costs.

- Less strain on the equipment thanks to the “V” profile on the rotor that provides stronger support and less friction.

- Category: Shredders

Description

| Type | EZ 6 |

|---|---|

| Throughput (approx for 16/20 screen) |

1-1.6 m3/hr of loose wood blocks |

| Hopper opening: | 600 x 800 mm |

| Hopper volume: | 0.6 m3 |

| Rotor Diameter: | 252 mm |

| Rotor Length: | 600 mm |

| Rotor Speed: | 60 – 100 rpm |

| Connection: | 200 mm |

| Dimensions (m): | 1.8L x 1.2W x 1.6H |

| Weight: | 1400 kg |

| Power Motor: | 18.5 kW |

| Cutting System: | 30 x 30 mm Concave headed cutters |

| Screen Size(mm): | 16/20 mm common for chipboard/mdf. 20/25mm common for pine off cuts. 10/12 mm common for briquetting . Variety of sizes available depending on required throughput |

| Throughput | Material composition and screen size will influence throughput rate |

| Control: | Electronic control using a PLC with controls housed in IP44 control cabinet |

| Voltage: | 400 V +/- 5% / 50 Hz |