Airtight Solutions proudly introduces its newest APM Series Pulse Jet Dust Collector System, our beautifully engineered Australia Made unit, featuring some fantastic features never before offered in such a compact unit.

The APMB has some unique engineered features which all work seamlessly to provide your workers with the safest, cleanest working environment possible.

Pound for pound, the APMB is in a class of its own. It is constructed with precision punched and folded 3mm thick powder coated mild steel, tough enough for any light to medium industrial process application and offers an affordable alternative to heavier fully welded units.

Its unique inlet louvre configuration knocks out fast-moving particulate and reduces turbulence, maximising filter efficiency and ensuring the longevity of the filters and collar wear. This saves significant amounts of money in maintenance, operating costs, and replacement parts.

Generously spaced polyester tubular filter bags minimises dust bridging, resulting in enduring performance and low running costs. Automatic online bag cleaning is activated by a solid-state timer.

The APMB’s top removal design makes maintenance access easy and safe, especially when working with toxic or corrosive materials. Combined with combustion relief functionality, the APMB pulse jet dust collector is one of the safest systems available today.

The cleverly engineered APMB is available in several standard configurations which can be specifically designed to your requirements. The APMB’s modular design enables additional cells and inlets to be retrofitted quickly, ensuring your new pulse jet extraction system can easily adapt and grow along with your business needs.

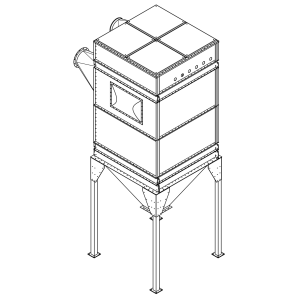

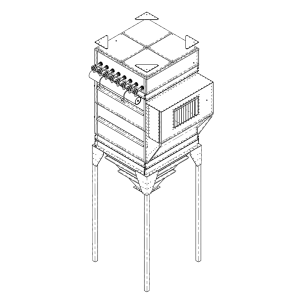

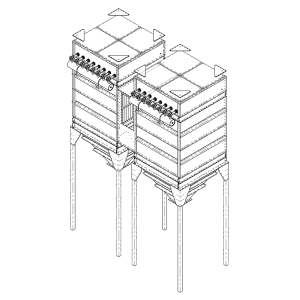

These 3 units are based around a standard 2.0m square footprint of the 100 shell (not including fan or external inlets). The 70/100 has an inlet in the body of the housing (BI), the 100 has an external louvre side entry inlet (SI), and 200 has a centre inlet essentially between 2 of the 100 units.

These units can be quickly erected on-site and have a multitude of dust discharge options. Rotary valves, slide gate and drums, and screw conveyors can be added to suit your specific reclaim or discharge requirements.

The reverse pulse cleaning system uses the latest venturi technologies for cleaning the bags, dragging additional air volume from the surrounding air to induce a more powerful shockwave cleaning action on the bags.

This is the most compact configuration available. The inlet is installed within the main unit.

By mounting the inlet louvre externally, significantly more space is created, resulting in more filter capacity.

Mounting a duel sided inlet louvre between two units provides you with the maximum capacity within our standard range.